Main business

contact us

Hebei Jimery Auto Parts Co., Ltd.Mainly engaged in the production and sales of metal stamping parts, molds, auto parts, motor parts, injection parts.The office address of Hebei Jimeirui Auto Parts Co., Ltd. is located in the petrochemical base and Cangzhou, an important land and sea transportation hub in the north, Dazhou Road, Wenmiao Town, Botou City, Cangzhou City, Hebei Province. The bureau was established with a registered capital of 3 million yuan. During the four years of the company ’s growth, we have always provided customers with good products and technical support, and sound after-sales service...

Mailbox: hebeijimeirui@163.com

Contact: Manager Xiao 0317-8296999

Automobile mould

Your Location: 首页>>Product center>>Die Design and Manufacturing-

Product Details

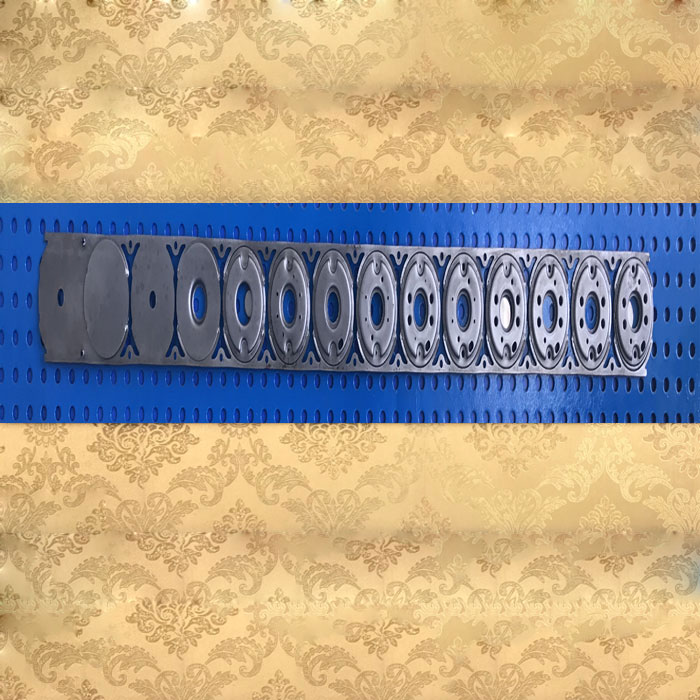

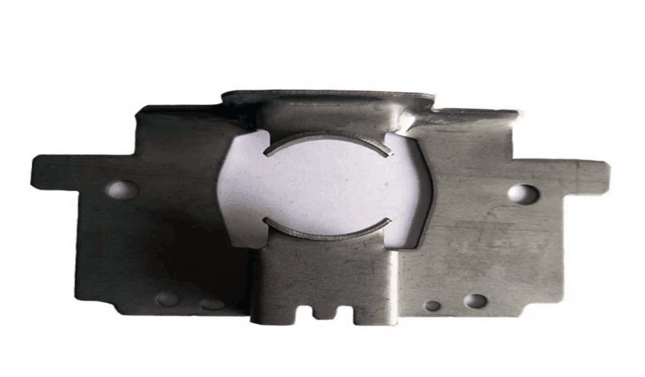

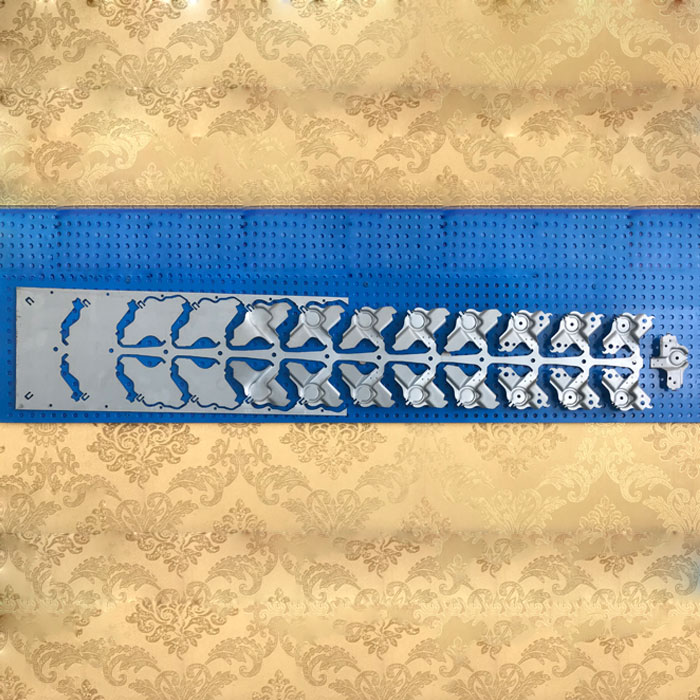

The main component of the automobile mold is the cover mold. This kind of mould is mainly a cold die. In a broad sense, "automobile mold" is a general name for all the molds that make all the parts on the automobile. For example, stamping mold, injection mold, forging mold, casting wax mold, glass mold, etc.Stamping parts on automobile bodies are generally divided into covering parts, beam frame parts and common stamping parts. Stamping parts that can clearly show the image characteristics of automobiles are automobile covers. Therefore, the more specific automobile die can be said to be "automobile panel stamping die". For short, the stamping die for automobile panels. For example, front door outer panel trimming die, front door inner panel punching die, etc.Of course, there are not only stamping parts on the car body. The dies of all stamping parts on automobiles are called "automobile stamping dies". To sum up, it is:1. The automobile mold is the general name of the mold for manufacturing all parts on the automobile.2. The automobile stamping die is the die for stamping all stamping parts on the automobile.3. The automobile body stamping die is a die for stamping all stamping parts on the automobile body.4. The stamping die for automobile covers is the die for stamping all covers on the automobile body.At present, when we talk about automobile dies in this plate, we all seem to be referring to stamping dies for automobile panels. In order not to confuse the general automobile die, the automobile cover die is used instead of the automobile die when posting.There are many forms of stamping dies. Stamping dies are also classified according to their working properties, die structure and die materials.Generally, it can be classified according to the following main features:1. Classification according to process propertiesA blanking die: a die that separates materials along closed or open contours. Such as blanking die, punching die, cutting die, cutting die, trimming die, cutting die, etc.B bending die: a die for bending blank or other blank along a straight line (bending line) to obtain workpieces with angles and shapes.C deep drawing die: it is a die that makes the blank of the sheet material into an open hollow part or further changes the shape and size of the hollow part.D forming die: it is a die that directly replicates and forms the blank or semi-finished workpiece according to the shape of the male and female dies in the drawing, while the material itself only produces local plastic deformation. Such as bulging die, necking die, flaring die, undulating forming die, flanging die, shaping die, etc.2. Classification according to process combination degreeA single process die: a die that only completes one stamping process in one stroke of the press.B. compound die: a die with only one station, and two or more stamping processes can be simultaneously completed at the same station in one stroke of the press.C progressive die (also called continuous die): a die with two or more work stations in the feeding direction of the blank, and two or more stamping processes are successively completed at different work stations in one stroke of the press.3, according to the product processing method classificationAccording to the different processing methods of products, moulds can be divided into five categories: punching and shearing moulds, bending moulds, drawing moulds, forming moulds and compression moulds.A punching and shearing die: the work is completed by shearing. the common forms are shearing die, blanking die, punching die, trimming die, whole edge die, drawing die and punching die.B bending die: the flat blank is bent into an angular shape. depending on the shape, precision and production of parts, there are many different forms of dies, such as common bending die, cam bending die, crimping die, circular arc bending die, bending punching die and twisting die.C. drawing mould: the drawing mould is to make the flat blank into a seamless container with a bottom.D. forming die: refers to various local deformation methods to change the shape of the blank, including convex forming die, rolling edge forming die, necking forming die, hole flange forming die and circular edge forming die.E compression mould: it uses strong pressure to make the metal blank flow and deform into the required shape. its types include extrusion die, embossing die, stamping die and end pressing die.

Advisory:Automobile mould

Links:

Technical Support:Hotspot marketing

中文

中文 English

English